How Energy Audits Support NABERS Improvement Plans

NABERS ratings influence leasing outcomes, asset value, and reputation across Australian commercial property. But improving a rating is not achieved through reporting alone. It requires operational change.

This is where a commercial energy audit plays a defined and practical role.

Energy Audits are not about providing NABERS ratings. Accredited assessors complete the rating process. We identify operational, plant, and control improvements that enable asset owners and facility teams to improve performance before the next assessment cycle.

Understanding the Gap Between Rating and Performance

A NABERS rating measures actual energy performance over a 12-month period. It reflects how your building truly operates.

What it does not automatically tell you is:

Why performance sits at its current level

Which systems drive inefficiency

Where base load is creeping up

Whether the plant is oversized or poorly controlled

What upgrades will deliver measurable improvement

An energy audit fills this gap.

For a broader overview of audit scope and methodology, see our Commercial and Industrial Energy Audits Australia page.

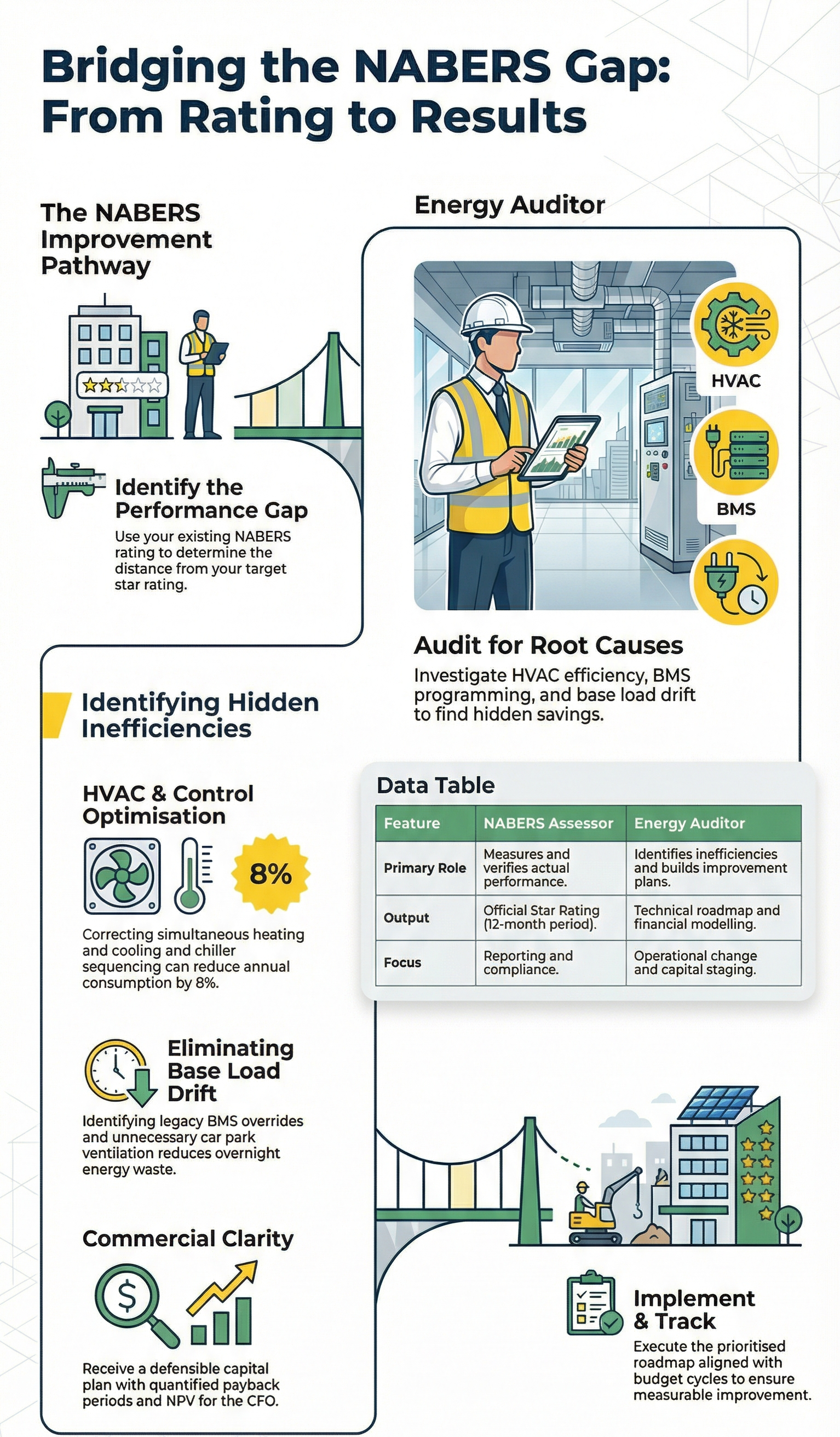

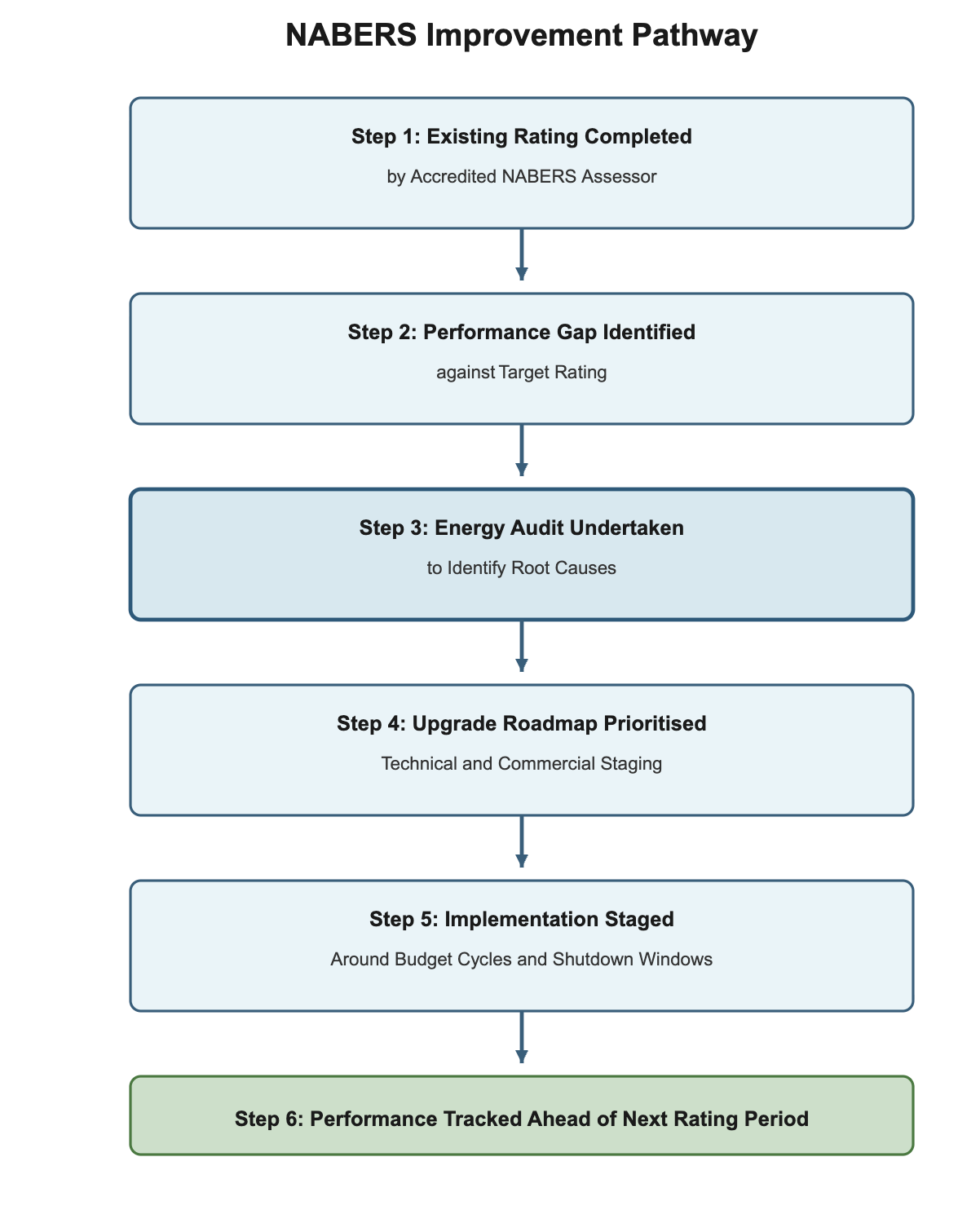

Where Energy Audits Sit in a NABERS Improvement Plan

A typical improvement pathway looks like this:

Existing rating completed by an accredited assessor

Performance gap identified against the target rating

An energy audit was undertaken to identify root causes

Upgrade roadmap prioritised

Implementation staged around budget cycles

Performance tracked ahead of the next rating period

The audit does not replace the rating. It informs the improvement strategy.

What an Energy Audit Typically Examines in NABERS-Driven Assets

In large, occupied commercial buildings, we focus on operational realities. Many of the sites we audit carry ageing plant that has been patched, overridden, or worked around over the years of reactive maintenance. Those workarounds often have a direct and measurable impact on energy consumption.

HVAC plant performance

Chiller and boiler efficiency

Cooling tower control

Pump and fan operation

After-hours operation and override management

Plant reliability issues that increase run hours or reduce efficiency

Base building lighting

Control logic

Zoning mismatches

Sensor failures

Central plant sequencing

Simultaneous heating and cooling

Poor setpoint alignment

Equipment short cycling

Base load drift

Car park ventilation

Supplementary condenser units

24-hour tenant loads impacting base building consumption

These issues are common in ageing CBD office towers and large multi-tenant assets. They are rarely visible in rating documentation alone.

Indicative Example

An example of what a Type 2 audit would provide for a 15,000 m2 commercial office building, the asset held a 4.5 Star NABERS Energy rating. The owner was targeting 5.5 Stars within two rating cycles.

The audit identified:

Continuous after-hours air handling on two floors due to legacy BMS programming

Simultaneous heating and cooling caused by control conflicts

Chiller sequencing inefficiencies during shoulder seasons

A 22 kW overnight base load tied to car park exhaust fans

Low-cost control optimisation reduced annual electricity consumption by approximately 8 per cent. A staged chiller upgrade and VSD retrofit roadmap was developed to support further improvement aligned with capex timing.

This did not guarantee a specific rating uplift. However, it provided the operational clarity needed to move toward the target rating with confidence.

How This Matters Commercially

For Asset Managers

You gain a defensible capital plan tied to measurable performance improvement.

You gain clarity on what to adjust now versus what requires shutdown planning and contractor coordination. When recommendations are staged around access windows and maintenance schedules, they are far more likely to move from the drawing board to the site.

You gain quantified energy savings, payback periods, and capital staging aligned to budget cycles.

For Sustainability Managers

You gain stronger evidence supporting Scope 2 reduction strategies and internal reporting.

Energy audits also support broader decarbonisation planning.

Common Constraints We See

Improving NABERS performance is rarely straightforward, and a useful audit has to account for the conditions on the ground.

An ageing plant is a constant factor. Chillers, air handling units, and BMS controllers that are 15 or 20 years old may still be running, but their efficiency has degraded, and their reliability is unpredictable. Facility managers often manage equipment past its optimal service life, balancing the cost of replacement against the risk of breakdown during peak operating periods.

Breakdowns and reactive maintenance shape what is actually possible. When a piece of plant fails unexpectedly, it disrupts upgrade planning, diverts contractor capacity, and often results in temporary workarounds that add to base load. An audit that is not aware of recent breakdown history or current reliability risks will produce a roadmap that does not reflect site reality.

Shutdown windows are limited. Occupied commercial buildings have narrow access opportunities for plant work. The audit recommendations need to be structured around what is achievable in planned outages, not ideal conditions.

Contractor coordination adds lead time and cost. Specialist trades are often booked well in advance, and sequencing upgrades across multiple contractors requires careful staging. Recommendations that assume open access and unlimited contractor availability are not useful.

An audit must recognise these realities. Recommendations that ignore operational constraints rarely get implemented.

What Decision Makers Receive

A NABERS-aligned energy audit typically delivers:

Clear breakdown of current energy drivers

Identified low-disruption improvements

Medium and long-term capital roadmap

Financial modelling, including payback and NPV

Risk commentary and implementation staging

For a full explanation of deliverables, see What You Receive From a Commercial Energy Audit.

The Separation of Roles

It is important to be clear.

NABERS assessors measure and verify performance.

Energy auditors analyse systems, identify inefficiencies, and build the improvement plan.

When both roles are clearly separated but coordinated, asset owners achieve better outcomes.

Taking the Next Step

If your asset has an existing rating and you are targeting improvement in the next cycle, now is the right time to investigate operational drivers, not three months before reassessment.

An energy audit provides the technical and commercial foundation required to move from rating ambition to measurable improvement.

If you would like to discuss your building, constraints, and target rating, contact us to discuss whether an audit is suitable for your site.

Find out about available energy saving grants and subsidies for your organisation on our Grants page.