Energy Audits for Manufacturing Facilities

Manufacturing sites use energy differently to most businesses. Energy is tied directly to output, uptime, and quality. When costs rise or reliability slips, production feels it first.

An energy audit for manufacturers gives you a clear view of how energy supports your operation today and where risk and cost sit beneath the surface.

This article explains how energy audits apply to manufacturing facilities, what they focus on, and how decision makers use them in practice.

Why does manufacturing energy use behave differently

In manufacturing, energy is not a background service. It is embedded in production.

Typical characteristics include:

High base loads that run regardless of demand

Energy use linked to production schedules

Equipment sized for peak loads but operated at part load

Process heat that is hard to recover or control

Compressed air and motors running outside production hours

This creates two problems.

First, energy waste is hidden in normal operations. It does not show up as a fault.

Second, energy cost and reliability risk rise together. Poor control leads to higher bills and more breakdowns.

An energy audit addresses both.

What an energy audit looks at in a manufacturing site

A manufacturing energy audit focuses on how energy flows through the site, not just how much is used.

It typically examines:

Electrical demand profiles across production and non-production periods

Process loads versus support systems

Control strategies and setpoints

Equipment sizing versus actual duty

Interaction between systems

This work sits within AS/NZS 3598 energy audit frameworks, scaled to suit the site size and decision need.

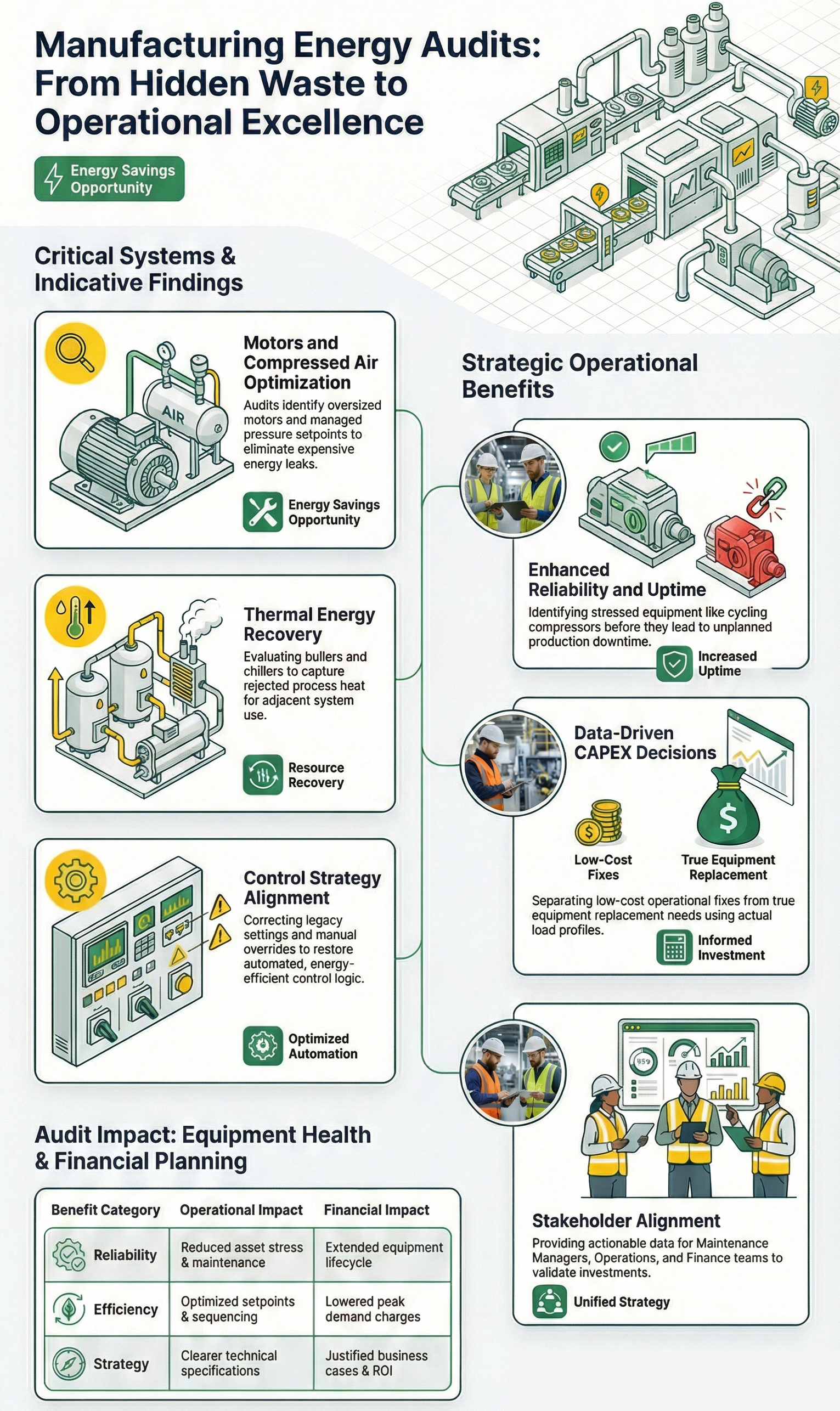

Key systems reviewed on site

While every manufacturing site differs, energy audits consistently focus on a core group of systems that drive cost, reliability, and operational risk. These systems usually run continuously, sit outside direct production control, or have changed over time without their energy impact being reassessed.

Motors and drives

Electric motors are often the largest single electricity load on site. Audits look at motor size, duty cycle, run hours, and how speed is controlled. Many motors are selected for worst-case scenarios and then operate most of their life at part load.

Typical finding. Large motors running continuously at low load with no Variable Speed Drive, creating unnecessary energy use and heat stress.

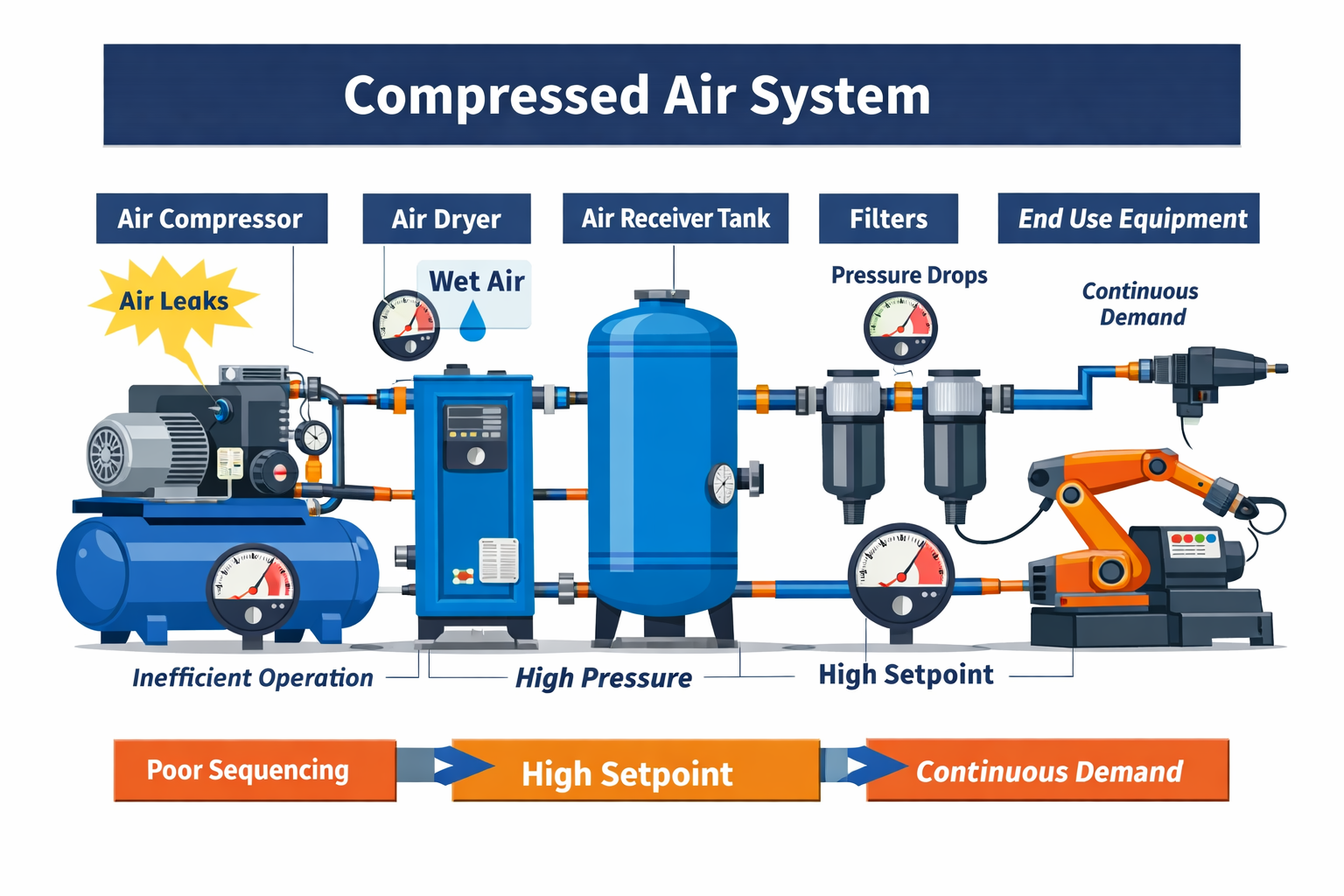

Compressed air

Compressed air is treated as a utility, but it is one of the most expensive on-site energy sources. Audits assess compressor sequencing, pressure setpoints, leaks, air quality requirements, and demand outside production hours.

Typical finding. Multiple compressors operating to maintain an elevated pressure setpoint driven by a small number of unmanaged ends.

Process heating and cooling

Boilers, furnaces, ovens, chillers, and cooling towers are reviewed as complete systems, not isolated assets. Audits examine how heat is generated, transferred, rejected, and controlled across production and standby modes.

Typical finding. Process heat is rejected to the atmosphere while adjacent processes rely on separate heating systems.

HVAC in production and support spaces

Manufacturing sites often condition areas that are partially occupied or only required during specific shifts. Audits assess zoning, scheduling, and interaction with process heat gains.

Typical finding. HVAC systems running full hours to maintain comfort in spaces with intermittent occupancy.

Controls, scheduling, and interlocks

Control systems often drift over time due to production changes, maintenance overrides, or legacy settings. Audits focus on how systems start, stop, and respond to load changes.

Typical finding. Equipment left in manual mode following maintenance, bypassing energy-efficient control logic.

Together, these systems usually account for most of the avoidable energy cost and operational risk identified in manufacturing energy audits.

How audits reduce cost without disrupting production

Manufacturing sites operate under tight constraints. Downtime is expensive. Changes must be justified.

Energy audits prioritise actions that:

Do not interfere with production

Reduce waste before proposing upgrades

Improve control rather than replace assets

Early-stage recommendations often include:

Shutdown and weekend energy control

Pressure and temperature setpoint correction

Sequencing and staging improvements

Fault identification that maintenance teams can action

These measures typically require limited capital and fit within existing maintenance cycles.

Larger upgrades are then assessed with clearer data and a better understanding of risk. Understanding energy audit costs early in the planning process helps budget holders evaluate options and make informed decisions.

How audits support reliability and uptime

Energy inefficiency often signals operational stress.

Examples include:

Compressors cycling excessively

Motors running hot due to oversizing or voltage issues

Boilers short-cycling

Cooling systems operating outside design conditions

Audits flag these issues early.

This allows you to:

Address root causes before failure

Reduce unplanned maintenance

Improve asset life

For operations and plant managers, this risk reduction often matters as much as cost savings.

Using audit outputs for capex decisions

Manufacturing sites often delay capital upgrades due to uncertainty.

An energy audit improves decision quality by:

Quantifying actual load profiles

Identifying which assets drive cost and risk

Separating operational fixes from true replacement needs

Audit reports typically include:

Prioritised opportunities

Indicative costs and savings

Simple payback ranges

Implementation considerations

This information supports internal business cases and aligns finance, operations, and maintenance.

For sites planning upgrades, audits also inform NABERS improvement plans where applicable.

Who typically uses this information

Manufacturing energy audits are read by multiple roles.

Facility and maintenance managers use them to:

Plan corrective works

Support shutdown planning

Brief contractors accurately

Operations managers use them to:

Understand energy drivers tied to output

Reduce variability and risk

CFOs and finance teams use them to:

Validate investment decisions

Forecast operating costs

Avoid underperforming upgrades

A good audit speaks to all three.

Common mistakes audits help avoid

Without an audit, manufacturing sites often:

Replace equipment that is not the real problem

Invest in efficiency projects with limited impact

Miss low-cost control improvements

Underestimate reliability risk

Audits do not promise guaranteed savings. They reduce uncertainty, thereby improving decisions.

Next steps

If you manage or oversee a manufacturing site, an energy audit provides clarity before cost or reliability become urgent problems. You can read more about us and our experience delivering energy audits.

Find out about available energy saving grants and subsidies for your organisation on our Grants page.