AS/NZS 3598 Energy Audits. What Each Type Means On Site

If you manage a commercial or industrial facility, you will see energy audits described as type 1, type 2, or type 3 under AS/NZS 3598. The standard sounds formal. The real question is simple. What actually happens on site, and which type makes sense for your building and budget.

This guide explains each audit type in practical terms. It focuses on what you will experience as a Facility Manager, the level of disruption to expect, and when each type is worth paying for.

What AS/NZS 3598 is used for

AS/NZS 3598 is the Australian and New Zealand standard that defines the scope and delivery of energy audits. It does not rate buildings. It sets expectations around audit depth, data quality, and outputs.

Most commercial and industrial energy audits in Australia reference this standard. Understanding the types helps you avoid audits that are either too light to be useful or too detailed for your site.

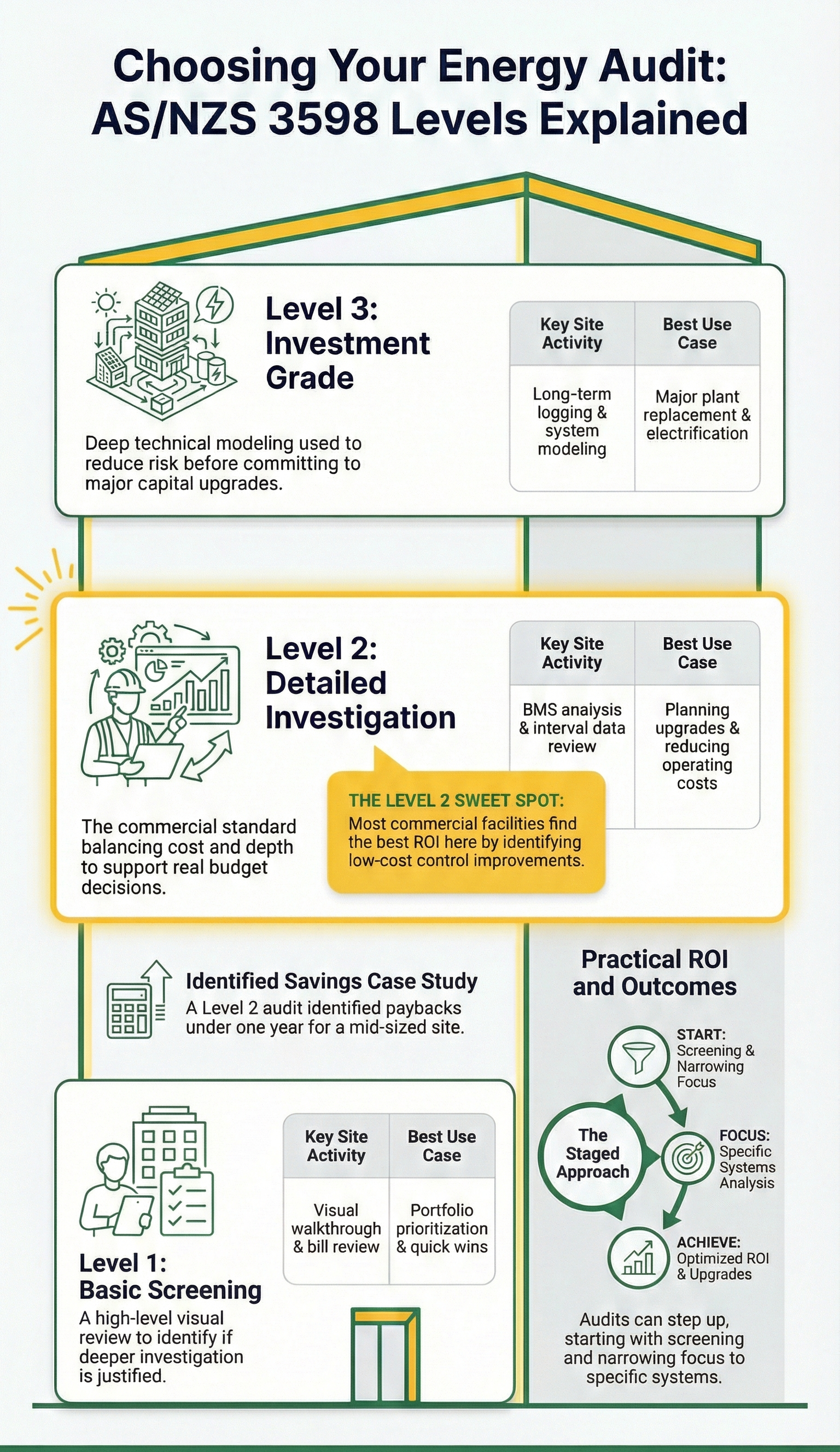

Type 1 Energy Audit. Basic screening on site

A type 1 audit is a high-type review. It is used to understand where energy is broadly consumed and whether a deeper investigation is justified. It answers the first and most common question you face as a Facility Manager. Is energy a real cost and risk issue at this site?

What happens on site

Short site walk-through during normal operations

Visual inspection of major plants such as HVAC, lighting, compressors, and process loads

Review of utility bills and interval data, if available

Practical conversation with site staff about operating hours, complaints, overrides and known problem areas

What you receive

Broad breakdown of energy use by system

List of obvious inefficiencies and quick wins

Indicative improvement opportunities that can be taken with minimal disruption

Clear guidance on whether a type 2 audit is likely to deliver value

What this means for you

A type 1 audit suits early-stage decision-making. It helps you answer one question. Is there enough opportunity here to justify further work?

It is useful when budgets are tight, when sites are small or simple, or when you manage a portfolio and need to prioritise which buildings need attention first.

It is not enough to support capital approvals or contractor scopes.

Type 2 Energy Audit. Detailed site investigation

A Type 2 audit is the most common audit type for commercial buildings. It balances depth with cost and disruption. For most Facility Managers, this is the point where an energy audit becomes a practical management tool rather than a high-level review.

This audit type is designed to support real decisions. It moves beyond identifying symptoms and starts explaining why energy is being used the way it is.

What happens on site

Detailed site inspection of plant rooms, switchboards, and controls

Review of BMS operation and schedules

Analysis of interval electricity and gas data to identify demand drivers and base load

Short-term monitoring, where required, such as temperature, power, or runtime

Discussions with maintenance contractors and site teams

The focus is on how systems interact, not just how they are designed to operate.

What you receive

Clear energy breakdown by system

Practical improvement actions that can be implemented by maintenance teams or contractors

Indicative capital and operating cost impacts for each action

Payback estimates are suitable for budget planning

Indicative example

In a recent type 2 audit of a mid-sized commercial hospitality site, total energy use was approximately 1,240 GJ per year, costing around $62,000 across electricity and gas. Interval data identified a consistent overnight base load of roughly 15-20 kW while the site was closed, driven mainly by refrigeration, hot water, and HVAC systems operating outside required hours. Low-cost control and setpoint changes, including hot water temperature adjustments and timer settings for refrigeration and glycol systems, were identified as short-term actions with paybacks of less than 1 year. The audit also outlined staged upgrades, including solar expansion, heat pump hot water, and the replacement of ageing HVAC and refrigeration plant, providing a clear, prioritised pathway to reduce annual energy costs by more than one-third over time.

What this means for you

A type 2 audit supports real decisions. It helps you build a maintenance or upgrade case backed by evidence rather than assumptions. It also helps you prioritise actions that reduce energy costs without increasing operational risk.

This type is typically used for large offices, shopping centres, hospitals, and most manufacturing sites where energy costs matter but full engineering modelling is not required. For manufacturing facilities specifically, audits often reveal opportunities in compressed air, process heating, and production scheduling that directly impact operating costs.

For many Facility Managers, this is the point where energy audits start to pay for themselves.

Type 3 Energy Audit. Investment-grade analysis

A Type 3 audit is a deep technical study. It is used where large capital decisions depend on the results. This type is selected when the cost, risk, or complexity of an upgrade makes indicative estimates insufficient.

The purpose of a Type 3 audit is confidence. It is designed to reduce uncertainty before committing significant capital.

What happens on site

Comprehensive data collection and validation

Detailed measurement and logging over longer periods

Engineering calculations and system modelling

Assessment of multiple upgrade scenarios

Coordination with designers, engineers, or OEMs if required

What you receive

Investment-grade analysis

High confidence savings estimates and assumptions are clearly documented

Inputs suitable for funding, board approval, or major upgrades

Clear risk and sensitivity considerations

What this means for you

A Type 3 audit is used when the stakes are high. Examples include major plant replacement, electrification projects, or large manufacturing process changes. For a Facility Manager, a Type 3 audit is used selectively. It makes sense when replacing major plants, electrifying gas systems, or making changes that affect reliability and long-term operating costs.

It requires more time, more access, and higher fees. It should only be used when the decision it supports justifies the effort.

How to choose the right audit type

For most sites, the decision is straightforward.

Use Type 1 to screen sites or identify if a problem exists

Use Type 2 to plan budgets, reduce operating costs, and stabilise performance

Use Type 3 to support large capital decisions

The decision often comes down to budget approval pathways. If you need to justify a larger capital request to a CFO or board, or if ageing equipment is creating breakdown risk, a Type 2 audit provides the evidence you need without months of disruption.

Many audits step up in stages. A Type 2 audit often builds on a Type 1 review. A Type 3 audit may focus solely on one system identified earlier, such as the central plant or the compressed air system.

How this works in real facilities

In large occupied commercial buildings, Type 2 audits are common because disruption must be controlled. Access windows are limited, and changes need to fit around tenants.

In manufacturing and industrial sites, Type 2 audits often focus on base load, control stability, and process scheduling before any deeper engineering work begins.

How Energyaudits applies AS/NZS 3598 in practice

We use AS/NZS 3598 as a scoping framework, not a box-ticking exercise.

Audits are sized to the decision you need to make. We avoid over-scoping when a simpler audit will deliver value. We also avoid under-scoping when you need defensible numbers for approvals.

This approach sits within our Commercial and Industrial Energy Audits Australia framework and ensures that audits remain practical, site-aware, and commercially useful.

Next step

If you're managing a site where energy costs are climbing, or equipment reliability is declining, the right starting point is usually a Type 2 audit. It provides the detail you need without over-engineering the process.

Request a commercial energy audit to discuss your site's constraints or contact us for a brief conversation about which audit type makes sense for your facility and budget.

Find out about available energy saving grants and subsidies for your organisation on our Grants page.